NFPA 70B Compliance: What Every Organization Should Know

Infrared inspections for safer, more reliable electrical systems

What is NFPA 70B?

NFPA 70B is the Recommended Practice for Electrical Equipment Maintenance, published by the National Fire Protection Association. In 2023, it was elevated from a “recommended practice” to a full standard, making compliance essential for organizations that want to reduce risk, improve safety, and meet insurance and regulatory requirements.

Why Does NFPA 70B Matter Now?

The shift from guideline to standard means that NFPA 70B is no longer optional. Facilities must now adopt structured maintenance programs for electrical systems. Infrared inspections play a central role in this process by identifying hidden faults before they become costly or dangerous.

Key reasons NFPA 70B is important:

Protects employees, tenants, and building occupants from electrical hazards

Reduces costly downtime caused by unplanned equipment failures

Helps facilities demonstrate compliance during audits and insurance reviews

Extends the life of critical electrical infrastructure

Who Should Implement NFPA 70B Standards?

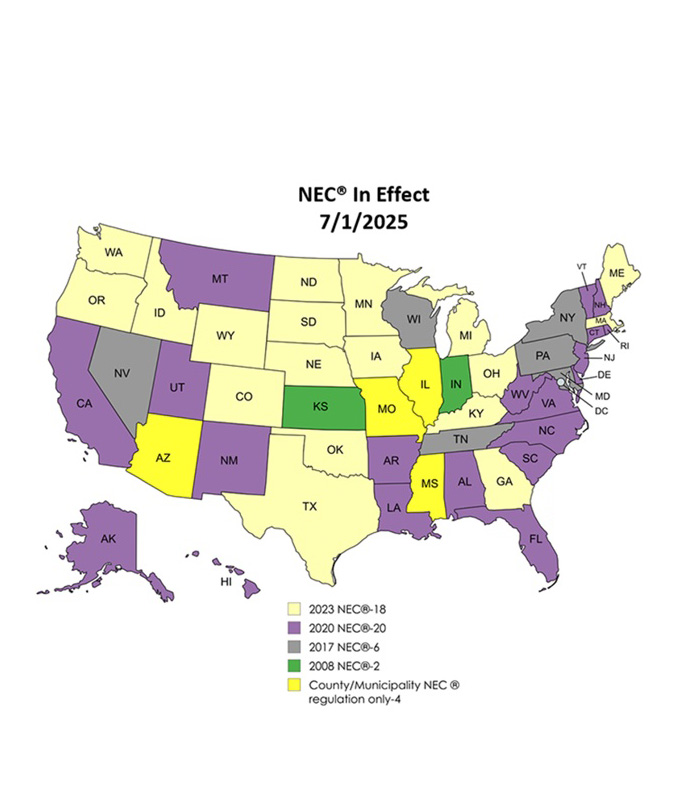

Any organization that owns or operates electrical systems in States that have adopted the 2023 National Electrical Code should implement the requirements set forth in NFPA-70B for maintenance and testing of electrical systems. These standards are not just for facility managers; they impact everyone involved in the safe and reliable operation of a building or facility.

- Facility Managers – Ensure overall building systems are maintained and compliant.

- Electrical & Maintenance Teams – Perform preventative maintenance and address issues identified during inspections.

- EHS (Environmental Health & Safety) Professionals – Protect employees, students, or patients by reducing electrical risks.

- Risk & Compliance Officers – Provide audit-ready documentation for insurers and regulators.

- Operations Managers – Maintain uptime for production lines, healthcare facilities, and other critical services.

- Property & Asset Managers – Protect investments by extending the life of electrical infrastructure and reducing liability.

- Utility Providers - Ensure that critical equipment for power grid reliability is scanned using infrared and corona camera technology.

By implementing NFPA 70B standards, these teams work together to reduce hazards, improve system reliability, and meet compliance expectations.

How Do Infrared Inspections Support NFPA 70B?

Infrared thermography is a proven tool for complying with NFPA 70B. By scanning electrical panels, switchgear, transformers, and distribution systems under load, thermographers can detect:

- Overheated connections

- Loose or corroded components

- Imbalanced loads

- Failing breakers and fuses

These findings are documented in clear reports, providing the evidence you need for maintenance planning, compliance records, and insurance support.

All electrical equipment must undergo a thermal imaging inspection at least every 12 months. Equipment identified with “Condition 3” issues in previous scans requires more frequent inspections—at least every 6 months.

Condition 3 designates equipment that has urgent issues or has significantly deviated from its expected operational state.

What Should Your Organization Do Next?

If you operate or oversee commercial, industrial, healthcare, municipal, or educational facilities, NFPA 70B applies to you. To stay compliant:

Establish a preventative maintenance program that includes infrared inspections.

Maintain thorough documentation for every inspection and corrective action.

Schedule routine thermographic scans to ensure ongoing compliance.

Why Brady Infrared?

Choosing the right partner for NFPA 70B compliance is critical. At Brady Infrared, we don’t just deliver reports — we help you build confidence in the safety and reliability of your electrical infrastructure.

- Proven Experience: 20+ years specializing in infrared inspections across industrial, commercial, healthcare, government, and educational facilities

- Certified Experts: Our team includes Level II and Level III thermographers and FAA-certified drone operators for safe, accurate inspections

- Actionable Reporting: Clear, easy-to-read reports with images and recommendations you can hand directly to your maintenance team or insurers

- Compliance Support: Reports are structured to align with NFPA 70B requirements and audit expectations, reducing risk and liability

- Risk Reduction: By identifying hot spots, loose connections, and overloaded equipment early, we help minimize downtime and extend asset life

When it comes to NFPA 70B compliance, Brady Infrared provides the expertise, technology, and documentation you need to protect your facility and maintain operational continuity.

Ready to Ensure NFPA 70B Compliance?

Don’t wait until a fault becomes a failure. Brady Infrared delivers the thermal inspections, documentation, and expertise you need to meet NFPA 70B standards — and keep your facility safe, reliable, and compliant.