Enhancing Electrical Safety with Infrared Inspection Windows

In today’s evolving workplace safety landscape, heightened awareness of potential hazards has led companies to reevaluate their safety protocols, particularly in environments where energized electrical equipment is prevalent. Among the myriad of risks, arc-flash incidents stand out as some of the most concerning occurrences within the electrical maintenance industry. As such, proactive measures to mitigate these risks are paramount, with a particular focus on improving safety during infrared inspections.

Understanding Arc-Flash Events

Arc-flash events represent violent energy releases that occur when there’s an unintended connection between phase-to-phase or phase-to-ground electrical conductors. The resulting explosion-like phenomenon can unleash a destructive wave of molten metal and extreme temperatures, posing significant risks to personnel and equipment alike. It’s important to note that the severity of arc-flash incidents hinges on two critical factors: the available fault current and the trip time of circuit breakers. Despite common misconceptions, higher voltage equipment doesn’t always equate to greater arc-flash energy. In fact, lower voltage equipment may pose heightened risks due to the delayed response of breakers to lower fault currents.

The Role of Infrared Inspection Windows

Enter infrared inspection windows – a proactive solution designed to reduce the risks associated with traditional infrared inspections. These specially designed ports provide a safe and efficient means of conducting inspections without the need to remove panel covers, thus minimizing direct exposure to energized equipment. By eliminating the need for physical contact with electrical components, infrared inspection windows significantly reduce the likelihood of arc-flash incidents during maintenance activities. Moreover, their installation facilitates quicker and more frequent inspections, enabling proactive maintenance and enhancing overall safety protocols.

Partnering with Brady Infrared

Brady Infrared stands as a trusted partner in the realm of electrical safety, offering a comprehensive range of infrared inspection windows and temperature monitoring devices. As a licensed distributor and installer of IRISS products, Brady Infrared provides solutions tailored to fit various electrical components seamlessly. With a diverse selection of sizes and designs, these infrared windows are engineered to meet the specific needs of different industries and applications. Whether it’s electrical switchgear, panels, motor terminal boxes, or iso-phase bus ducts, Brady Infrared has the expertise and resources to ensure your workplace remains safe and compliant.

Prioritizing Safety

Prioritizing safety in environments with energized electrical equipment is imperative, especially in light of the potential risks associated with arc-flash incidents. By implementing proactive measures such as the installation of infrared inspection windows, companies can significantly enhance workplace safety while streamlining maintenance operations. Partnering with a reputable provider like Brady Infrared ensures access to high-quality solutions that meet the rigorous demands of modern workplaces. Take proactive steps towards a safer work environment by integrating infrared inspection windows into your safety protocols.

Comprehensive Electrical Inspection Services by Certified Thermographers

Comprehensive Infrared Electrical Inspections We offer a comprehensive range of inspection services

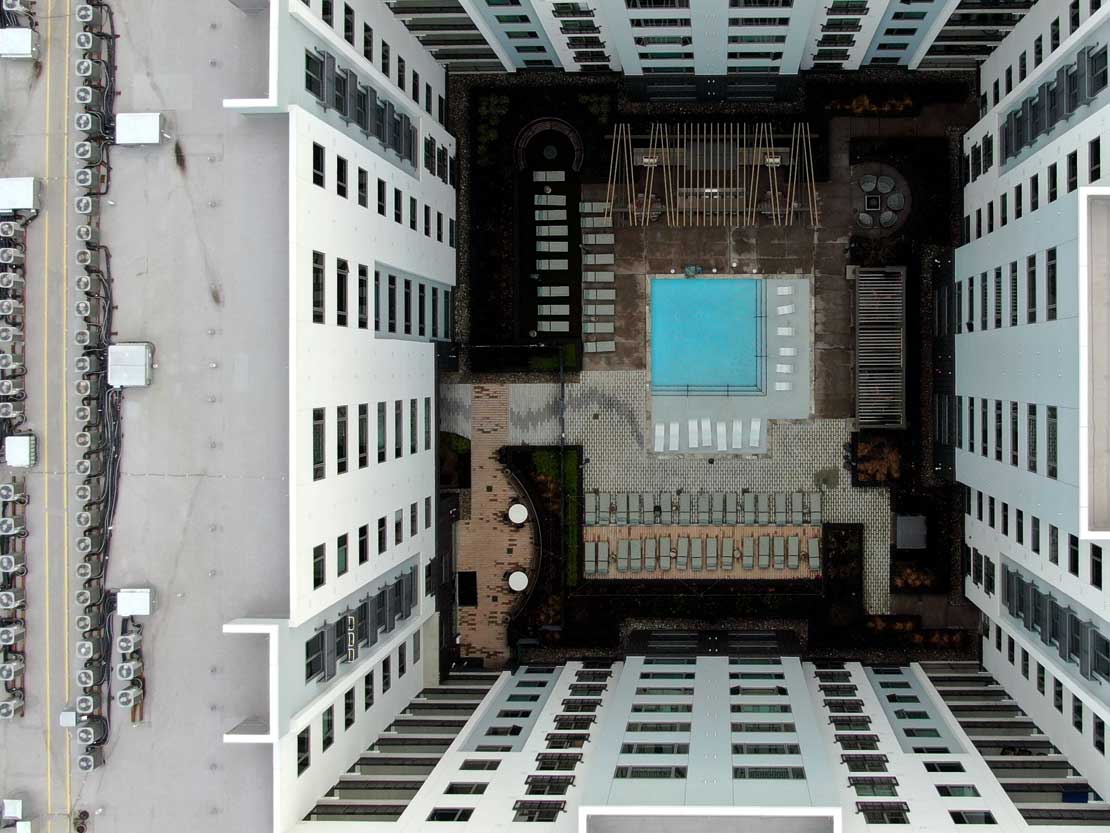

Revolutionize Building Inspections with Drone-Based Façade Assessments by Brady Infrared

Enhance Building Integrity with Innovative Drone-Based Façade Assessments Elevate your building mai

Enhancing Electrical Safety with Infrared Inspection Windows

In today’s evolving workplace safety landscape, heightened awareness of potential hazards has